- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

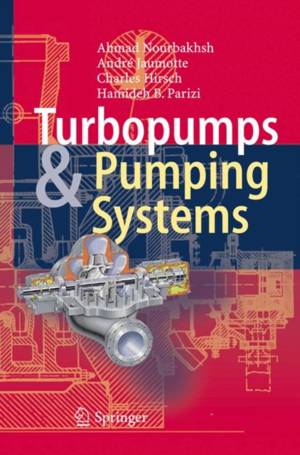

Turbopumps and Pumping Systems

Ahmad Nourbakhsh, André Jaumotte, Charles Hirsch, Hamideh B Parizi

Paperback | Engels

€ 116,45

+ 232 punten

Uitvoering

Omschrijving

Pumps are one of the mechanical devices that are widely used in many industries throughout the world. Turbopumps which are common types of pumps are used mainly for transporting water in agricultural units, industrial processes, cooling and heating systems, and power plants. But their application is not limited only for h- dling water. Turbopumps can be used for transporting oil products in oil and gas industries and re neries, as well as byproductsin pulp and paper industry, food and beverage in food industry, and contaminated water in sewage systems. Because of the versatility of pump usage, the numberof turbopumpsin operation worldwide is very large and as a result the total energy consumption of these units can be considerable. To reduce the energy consumption by turbopumps, it is imp- tant to increase the ef ciency of the pumps, as well as the system they are working in. The pump manufacturing companies and design engineers are constantly trying to improve the performances of pumps by designing more ef cient pumps and by using the latest technologies available in terms of design software, new developed materials, and state of the art manufacturing tools. Today, computational uid - namics and sophisticated design software tools help designers to optimize the uid ow inside the pumps and to design different pump elements with better hydraulic ef ciencies. However, the operation of turbopumps can be optimized a well by effectively using proper pumps and designing ef cient piping systems.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 184

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9783642064210

- Verschijningsdatum:

- 12/02/2010

- Uitvoering:

- Paperback

- Formaat:

- Trade paperback (VS)

- Afmetingen:

- 156 mm x 234 mm

- Gewicht:

- 303 g

Alleen bij Standaard Boekhandel

+ 232 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.