- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

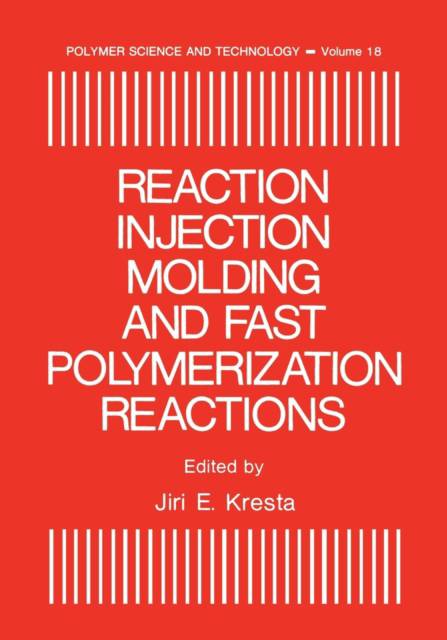

Reaction Injection Molding and Fast Polymerization Reactions

Jiri E Kresta, International Symposium on Reaction Injection Molding, American Chemical Society Division of Organic Coati

€ 83,95

+ 167 punten

Omschrijving

The emergence of reaction injection molding (RIM) has been fol- lowed by the industry with mounting interest. RIM technology has brought to polymer processing a new flexibility and savings in both energy and capital investment. The new developments and the number of engineers and scientists working in RIM is growing at so fast a rate that there is need for sharing information on progress in this area. This book is based on papers presented at the International Symposium on Reaction Injection Molding which was held in 1981 in Atlanta, Georgia, and was sponsored by the American Chemical Society, Division of Organic Coatings and Plastics Chemistry. The book is divided into four parts covering different areas of RIM development. The first part is devoted to the future trends of RIM develop- ment in the United States and Japan. The structure-properties relationship and effects of annealing on properties of RIM elastomers are covered in the second part. New non-urethane polymers such as polyamides, polyisocyanurates and polystyrene suitable for RIM processing are discussed in the third part. In the last part the engineering and technological aspects of RIM, such as glass reinforcement, mixing, flow and moldability are covered in detail. Finally I would like to thank Mrs. Iris Glebe for typing this book and for help with editing, and K. Zielinski for his assistance v vi PREFACE in reviewing and, when necessary, correcting some of the papers. Thanks is also due to the editors of Plenum for their patience and helpfulness.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 302

- Taal:

- Engels

- Reeks:

- Reeksnummer:

- nr. 18

Eigenschappen

- Productcode (EAN):

- 9781468487350

- Verschijningsdatum:

- 15/06/2012

- Uitvoering:

- Paperback

- Formaat:

- Trade paperback (VS)

- Afmetingen:

- 178 mm x 254 mm

- Gewicht:

- 548 g

Alleen bij Standaard Boekhandel

+ 167 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.