- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

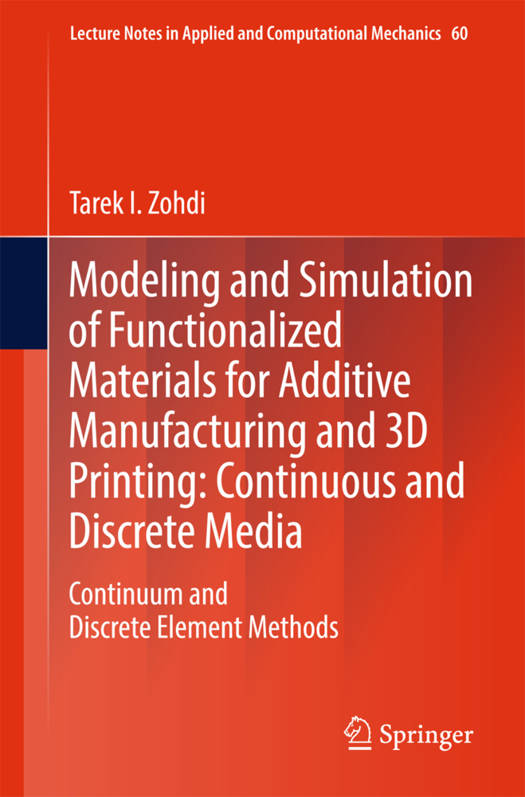

Modeling and Simulation of Functionalized Materials for Additive Manufacturing and 3D Printing: Continuous and Discrete Media

Continuum and Discrete Element Methods

Tarek I ZohdiOmschrijving

Within the last decade, several industrialized countries have stressed the importance of advanced manufacturing to their economies. Many of these plans have highlighted the development of additive manufacturing techniques, such as 3D printing which, as of 2018, are still in their infancy. The objective is to develop superior products, produced at lower overall operational costs. For these goals to be realized, a deep understanding of the essential ingredients comprising the materials involved in additive manufacturing is needed. The combination of rigorous material modeling theories, coupled with the dramatic increase of computational power can potentially play a significant role in the analysis, control, and design of many emerging additive manufacturing processes. Specialized materials and the precise design of their properties are key factors in the processes. Specifically, particle-functionalized materials play a central role in this field, in three main regimes:

(1) to enhance overall filament-based material properties, by embedding particles within a binder, which is then passed through a heating element and the deposited onto a surface,

(2) to "functionalize" inks by adding particles to freely flowing solvents forming a mixture, which is then deposited onto a surface and

(3) to directly deposit particles, as dry powders, onto surfaces and then to heat them with a laser, e-beam or other external source, in order to fuse them into place.

The goal of these processes is primarily to build surface structures which are extremely difficult to construct using classical manufacturing methods. The objective of this monograph is introduce the readers to basic techniques which can allow them to rapidly develop and analyze particulate-based materials needed in such additive manufacturing processes. This monograph is broken into two main parts: "Continuum Method" (CM) approaches and "Discrete Element Method" (DEM) approaches. The materials associated with methods (1) and (2) are closely related types of continua (particles embedded in a continuous binder) and are treated using continuum approaches. The materials in method (3), which are of a discrete particulate character, are analyzed using discrete element methods.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 298

- Taal:

- Engels

- Reeks:

- Reeksnummer:

- nr. 60

Eigenschappen

- Productcode (EAN):

- 9783319700779

- Verschijningsdatum:

- 22/12/2017

- Uitvoering:

- Paperback

- Formaat:

- Trade paperback (VS)

- Afmetingen:

- 156 mm x 234 mm

- Gewicht:

- 449 g

Alleen bij Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.