- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

Omschrijving

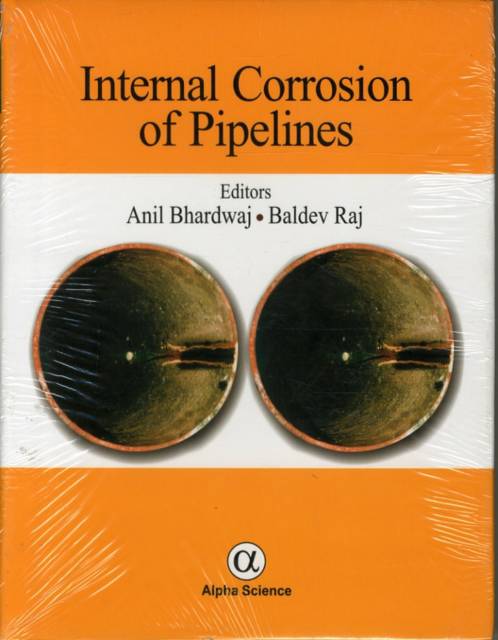

Discusses various factors responsible for internal corrosion of pipelines, which include corroding gases like O2, CO2, H2S; different types of bacteria; environmental factors such as temperature and pressure; aqueous chemistry including salinity, buffer ion concentration, ionic composition and pH; flow regimes in case of multiphase flow etc.

Mechanisms, causes and effects have been explained in user-friendly language with apt case studies and examples. Internal corrosion of pipes in seawater environment is a very specific issue relevant to coastal, offshore and shipping industry. The options of corrosion resistant materials and corrosion control have been elaborated which can vary depending upon requirement of industry, temperature and flow conditions. Two types of pipeline systems are common to most chemical process industries, viz. cooling water and firewater. They are essential for efficient and safe operation of a chemical process plant. The environmental and flow conditions are different for these lines and unique corrosion control measures, including specific materials of construction, for these two categories of lines have been dealt in this book in separate chapters. A discussion on composite materials has also been included, which are fast emerging as corrosion resistant materials for several environments of pipelines. Corrosion control and monitoring go hand-in-hand and therefore, the aspect of corrosion monitoring and inspection has also been duly covered in this book. Finally, there is a chapter on holistic approach to handle corrosion through corrosion management tools. The chapters have been written by experts in the respective fields. Certainly, this book will be a treasure for all those involved with pipelines in variety of environments of various industries.

Mechanisms, causes and effects have been explained in user-friendly language with apt case studies and examples. Internal corrosion of pipes in seawater environment is a very specific issue relevant to coastal, offshore and shipping industry. The options of corrosion resistant materials and corrosion control have been elaborated which can vary depending upon requirement of industry, temperature and flow conditions. Two types of pipeline systems are common to most chemical process industries, viz. cooling water and firewater. They are essential for efficient and safe operation of a chemical process plant. The environmental and flow conditions are different for these lines and unique corrosion control measures, including specific materials of construction, for these two categories of lines have been dealt in this book in separate chapters. A discussion on composite materials has also been included, which are fast emerging as corrosion resistant materials for several environments of pipelines. Corrosion control and monitoring go hand-in-hand and therefore, the aspect of corrosion monitoring and inspection has also been duly covered in this book. Finally, there is a chapter on holistic approach to handle corrosion through corrosion management tools. The chapters have been written by experts in the respective fields. Certainly, this book will be a treasure for all those involved with pipelines in variety of environments of various industries.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 374

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9781842659366

- Verschijningsdatum:

- 30/01/2015

- Uitvoering:

- Hardcover

- Formaat:

- Genaaid

- Afmetingen:

- 184 mm x 241 mm

- Gewicht:

- 784 g

Alleen bij Standaard Boekhandel

+ 167 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.