- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

€ 210,95

+ 421 punten

Uitvoering

Omschrijving

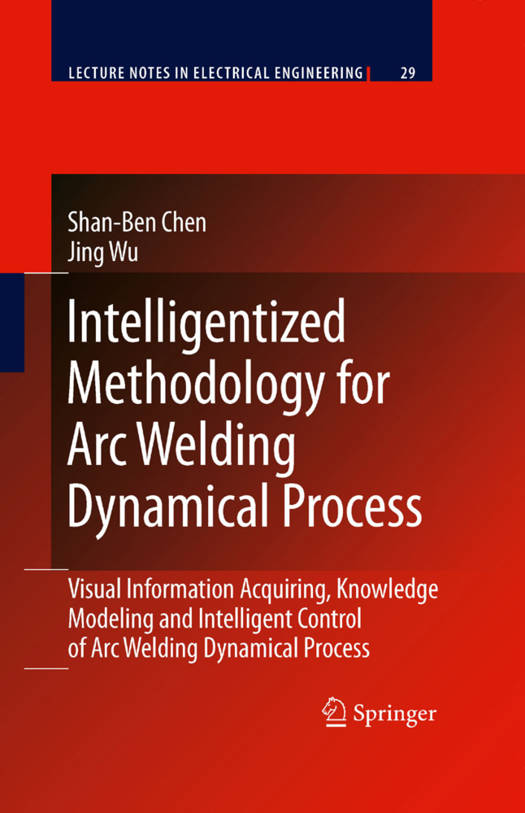

Welding handicraft is one of the most primordial and traditional technics, mainly by manpower and human experiences. Weld quality and ef?ciency are, therefore, straitly limited by the welder's skill. In the modern manufacturing, automatic and robotic welding is becoming an inevitable trend. However, it is dif?cult for au- matic and robotic welding to reach high quality due to the complexity, uncertainty and disturbance during welding process, especially for arc welding dynamics. The information acquirement and real-time control of arc weld pool dynamical process during automatic or robotic welding always are perplexing problems to both te- nologist in weld ?eld and scientists in automation. This book presents some application researches on intelligentized methodology in arc welding process, such as machine vision, image processing, fuzzy logical, neural networks, rough set, intelligent control and other arti?cial intelligence me- ods for sensing, modeling and intelligent control of arc welding dynamical process. The studies in the book indicate that the designed vision sensing and control s- tems are able to partially emulate a skilled welder's intelligent behaviors: observing, estimating, decision-making and operating, and show a great potential and prom- ing prospect of arti?cial intelligent technologies in the welding manufacturing.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 278

- Taal:

- Engels

- Reeks:

- Reeksnummer:

- nr. 29

Eigenschappen

- Productcode (EAN):

- 9783540856412

- Verschijningsdatum:

- 4/11/2008

- Uitvoering:

- Hardcover

- Formaat:

- Genaaid

- Afmetingen:

- 163 mm x 239 mm

- Gewicht:

- 566 g

Alleen bij Standaard Boekhandel

+ 421 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.