- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

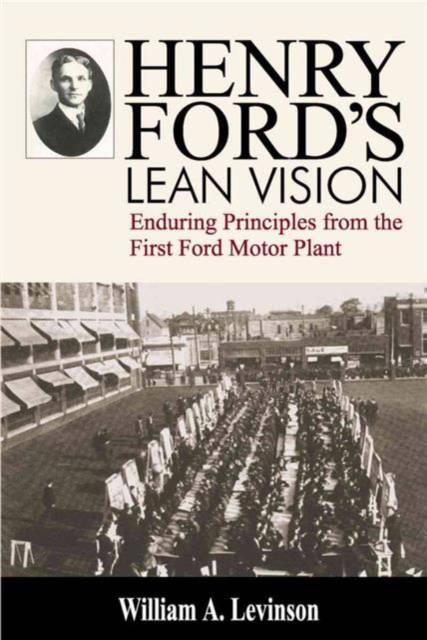

Henry Ford's Lean Vision

Enduring Principles from the First Ford Motor Plant

William A LevinsonOmschrijving

Praise from Industry Week, January 2003

"...In Henry Ford's Lean Vision...Levinson shows how the father of American mass production toiled to eliminate waste, instituted just-in-time delivery of inventory, and applied many other tools now identified with lean..."

Japanese manufacturers have made concepts like kaizen (continuous improvement), poka-yoke (error-proofing), and just-in-time famous. When the Japanese began to adopt these techniques from the Ford Motor Company during the early twentieth century, they knew exactly what they were getting: proven methods for mass-producing any product or delivering any service cheaply but well.

Henry Ford's methods, however, went well beyond the synergistic and mutually supporting techniques that constitute what we now call lean manufacturing. They included the "soft sciences," the organizational psychology that makes every employee a partner in the drive for success.

In Henry Ford's Lean Vision, William A. Levinson draws from Henry Ford's writings, the procedures in his factories, and historical anecdotes about the birth of lean in Japan to show that the philosophy that revolutionized Japanese manufacturing was the same philosophy that grew the Ford Motor Company into a global powerhouse -- and made the United States the wealthiest and most powerful nation on earth. Levinson reveals how Ford was ahead of other modern visionaries and discusses why the very ideas that made his company such a success were abandoned in his own country, and why they finally found acceptance in Japan.

Henry Ford's Lean Vision is a hands-on reference that provides the reader with proven principles and methods that can be applied in any business or service enterprise. It covers all aspects of building and running a successful enterprise, including Ford's principles for human relationships and the management of physical resources.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 400

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9781563272608

- Verschijningsdatum:

- 10/09/2002

- Uitvoering:

- Hardcover

- Formaat:

- Genaaid

- Afmetingen:

- 156 mm x 237 mm

- Gewicht:

- 725 g

Alleen bij Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.