- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

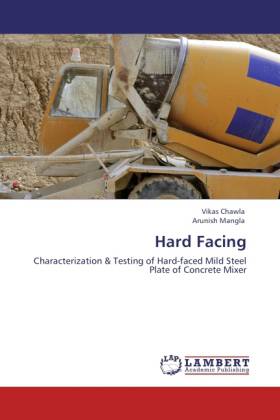

Hard Facing

Characterization & Testing of Hard-faced Mild Steel Plate of Concrete Mixer

Vikas Chawla, Arunish Mangla

Paperback | Engels

€ 48,45

+ 96 punten

Omschrijving

Hardfacing by welding is the most economic way to enhance the life of the components which are exposed to high abrasion environment. Chromium rich electrodes are widely used due to their low cost. It is planned to study the effect of carbon and chromium over a wide range, on the resultant microstructure as well as wear behavior of the deposited layers, of the bottom plate of concrete mixer used in ready mix concrete plant.Six types of iron-based hardfacing electrodes with a wide range of C (0.6-5% by wt.) and Cr (3.5-35% by wt.) were selected to deposit, by the manual metal arc welding process on the mild steel plate of concrete mixer. The abrasive wear responses, hardness and the microstructures were compared with that of mild steel.Abrasion tests were carried out in a sliding wear abrasion test machine. surface analysis were made using SEM-EDAX, XRD Analysis.Field test was performed, by hardfacing on the actual size mild steel plate.The extent of improvement in wear performance of mild steel due to all hardfacing alloys is quite appreciable as compared to mild steel. Further the life of hardfaced plate was enhanced by 3.11 times compared to mild steel plate resulting net cost

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 76

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9783847327776

- Verschijningsdatum:

- 27/12/2011

- Uitvoering:

- Paperback

- Afmetingen:

- 152 mm x 229 mm

- Gewicht:

- 122 g

Alleen bij Standaard Boekhandel

+ 96 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.