- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

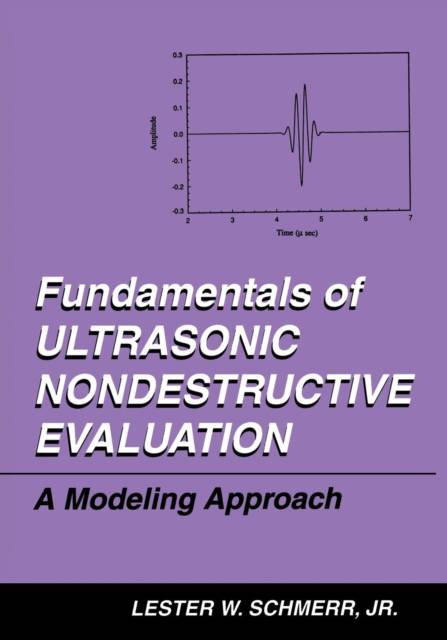

Fundamentals of Ultrasonic Nondestructive Evaluation

A Modeling Approach

Lester W Schmerr Jr

Paperback | Engels

€ 279,45

+ 558 punten

Uitvoering

Omschrijving

Ultrasound is currently used in a wide spectrum of applications ranging from medical imaging to metal cutting. This book is about using ultrasound in nondestructive evaluation (NDE) inspections. Ultrasonic NDE uses high-frequency acoustic/elastic waves to evaluate components without affecting their integrity or performance. This technique is commonly used in industry (particularly in aerospace and nuclear power) to inspect safety-critical parts for flaws during in-service use. Other important uses of ultrasonic NDE involve process control functions during manufacturing and fundamental materials characterization studies. It is not difficult to set up an ultrasonic NDE measurement system to launch waves into a component and monitor the waves received from defects, such as cracks, even when those defects are deep within the component. It is difficult however to interpret quantitatively the signals received in such an ultrasonic NDE measurement process. For example based on the ultrasonic signal received from a crack, what is the size, shape, and orientation of the crack producing the signal? Answering such questions requires evaluation procedures based on a detailed knowledge of the physics of the entire ultrasonic measurement process. One approach to obtaining such knowledge is to couple quantitative experiments closely with detailed models of the entire ultrasonic measurement system itself. We refer to such models here as ultrasonic NDE measurement models. In other areas of engineering, models have revolutionized how engineering is practiced. A classic example is the impact of the finite-element method on elastic stress analysis.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 559

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9781489901446

- Verschijningsdatum:

- 14/06/2013

- Uitvoering:

- Paperback

- Formaat:

- Trade paperback (VS)

- Afmetingen:

- 178 mm x 254 mm

- Gewicht:

- 984 g

Alleen bij Standaard Boekhandel

+ 558 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.