- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

€ 22,95

+ 45 punten

Omschrijving

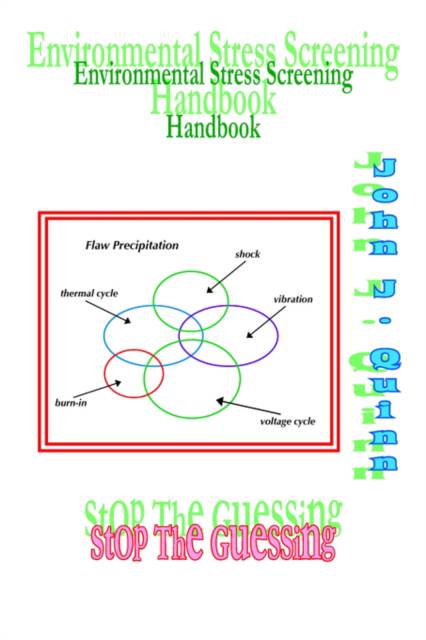

Why read this book on Environmental Stress Screening If you are working in the electronic manufacturing industry and you have heard the questions: "Why did it fail in the field and not in the factory ?" The answer to this question is there was not a proper ESS program developed for this product. A good ESS program is develop from the ground up and the fallout data is tracked. The fallout data is used to alter the present ESS program. This new /altered program is tailored to the hardware and usually is less costly and should improve the product reliability. "Why can't we use the same ESS program as the other guy ?" The answer to this is you can, if you are manufacturing the exact same product. If this is the case, you must be working with the other guy. A different product requires a different ESS program. Or If you are working in the electronic manufacturing industry and you have heard the statements: "I won't do ESS, it's going to cost too much." Can you put a price on field returns or lost contracts because of poor quality ? "I don't need to ESS, I'll just be more careful during manufacturing." You can be as careful as you want. If you don't weed out the Latent defects the time bomb is ticking. Or (worst case condition) If you are working in the electronic manufacturing industry and you have heard the front door being locked for the last time because of poor Quality hardware being shipped to the customer: Unfortunately if this happens it is too late to do anything. Hopefully you will develop a strong ESS program that is cost effective, apply dynamic management of the ESS program by analyzing the fallout data and last but not least - use common sense.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 160

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9781418428198

- Verschijningsdatum:

- 9/09/2004

- Uitvoering:

- Paperback

- Formaat:

- Trade paperback (VS)

- Afmetingen:

- 152 mm x 229 mm

- Gewicht:

- 244 g

Alleen bij Standaard Boekhandel

+ 45 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.