- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

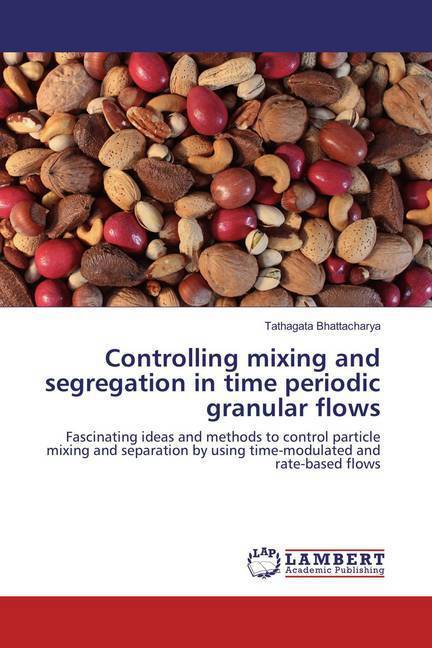

Controlling mixing and segregation in time periodic granular flows

Fascinating ideas and methods to control particle mixing and separation by using time-modulated and rate-based flows

Tathagata Bhattacharya

Paperback | Engels

€ 70,95

+ 141 punten

Omschrijving

The discrete element method (DEM) is considered the gold standard for simulating particle flows. In this book, DEM is employed to investigate the mixing and segregation of granular material in various prototypical solid handling devices commonly found in process industries. Recently, it has been suggested that segregation in particle mixers can be thwarted if the particle flow is inverted at a rate above a critical forcing frequency. Based on the above hypothesis, various configurations of solid mixers (rotating drums) are numerically and experimentally studied to investigate the conditions for improved mixing. In addition, an experimentally validated DEM model is used to find the critical chute length for segregation based on the above hypothesis of time modulation. While segregation is often an undesired effect, sometimes separating the components of a particle mixture is the ultimate goal. Here, two examples of novel rate-based separation devices are demonstrated that have the potential to revolutionize the way particles are separated today across many industries by providing an alternate "energy efficient" and "green" means of performing this economically important task.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 204

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9783659865749

- Uitvoering:

- Paperback

- Afmetingen:

- 150 mm x 220 mm

Alleen bij Standaard Boekhandel

+ 141 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.