- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

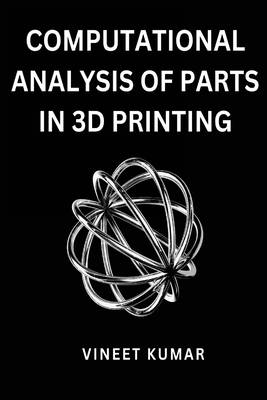

Omschrijving

Today the need for products and its consumptions rate are accelerating the technological

as well as economic competition between the manufacturing organisations and

customers. At present, every customer requires customised and low-cost product. Day by

day the increasing competition between companies is forcing manufacturing groups to

develop new technologies to improve their manufacturing processes. These new

technologies improve product quality and reduce product cycle time to fulfil the customer

demand. Every organisation's priority is to fulfil the customer's needs at the right time

for its survival.

Today the increased use of social media constantly changes the society's taste from time

to time which dramatically impacts the traditional industry. Due to market competition,

every manufacturing organisation changes their strategy according to current trends,

feedback and customer reviews to meet the customer's demand.

Every customer needs customised product at a low cost with the best quality in short lead

time. Today, every organisation is shifting towards new technology. The computer

technology customises the product using 3D CAD modelling software in shorter time.

The traditional manufacturing processes have geometrical limitations. The geometrical

limitations are eliminated by new technologies like rapid prototyping, which play a vital

role to meet customer demands.

Today, Additive Manufacturing Technology has widely spread in aerospace, defence,

dental, prostheses, implants, etc. The consumer industry like sports, furniture and

jewellery are aware of the advantages and significant role for their businesses in future.

Rapid Prototyping Processes can be defined as the technique in which any geometry can

be printed using 2D section by adding a thin section, layer by layer on top of each other

in the limited printed area with specified input conditions. On completion of the building

process, it is taken out from printed area, and post-processing operations are conducted to

remove unwanted material or support structure from the base. In post processing after

removing support structure, pin holes, cracks and void are filled by some bonding

material for strengthening the part

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 196

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9787357580973

- Verschijningsdatum:

- 31/10/2022

- Uitvoering:

- Paperback

- Formaat:

- Trade paperback (VS)

- Afmetingen:

- 152 mm x 229 mm

- Gewicht:

- 267 g

Alleen bij Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.