Door een staking bij bpost kan je online bestelling op dit moment iets langer onderweg zijn dan voorzien. Dringend iets nodig? Onze winkels ontvangen jou met open armen!

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Door een staking bij bpost kan je online bestelling op dit moment iets langer onderweg zijn dan voorzien. Dringend iets nodig? Onze winkels ontvangen jou met open armen!

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

€ 419,45

+ 838 punten

Uitvoering

Omschrijving

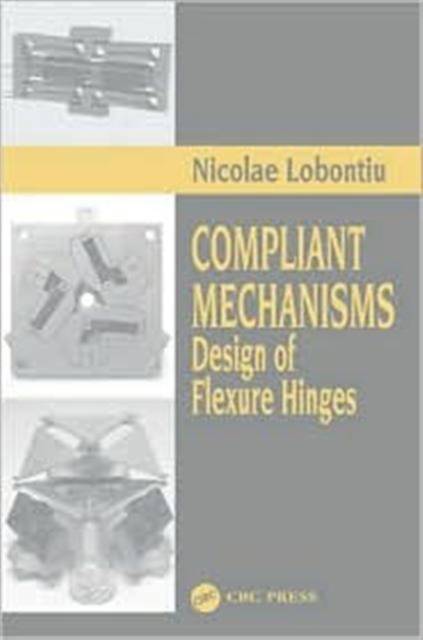

Flexure hinges hold several advantages over classical rotation joints, including no friction losses, no need for lubrication, no hysteresis, compactness, capacity to be utilized in small-scale applications, ease of fabrication, virtually no assembly, and no required maintenance. Compliant Mechanisms: Design of Flexure Hinges provides practical answers to the present and future needs of efficient design, analysis, and optimization of devices that incorporate flexure hinges. With a highly original approach the text: Discusses new and classical types of flexure hinges (single-, two- and multiple-axis) for two- and three-dimensional applications

Addresses a wide range of industrial applications, including micro- and nano-scale mechanisms

Quantifies flexibility, precision of rotation, sensitivity to parasitic loading, energy consumption, and stress limitations through closed-form compliance equations

Offers a unitary presentation of individual flexure hinges as fully-compliant members by means of closed-form compliance (spring rates) equations

Fully defines the lumped-parameter compliance, inertia and damping properties of flexure hinges

Develops a finite element approach to compliant mechanisms by giving the elemental formulation of new flexure hinge line elements

Incorporates more advanced topics dedicated to flexure hinges including large deformations, buckling, torsion, composite flexures, shape optimization and thermal effects Compliant Mechanisms: Design of Flexure Hinges provides practical answers and directions to the needs of efficiently designing, analyzing, and optimizing devices that include flexure hinges. It contains ready-to-use plots and simple equations describing several flexure types for the professional that needs quick solutions to current applications. The book also provides self-contained, easy-to-apply mathematical tools that provide sufficient guidance for real-time problem solving of further applications.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9780849313677

- Verschijningsdatum:

- 27/12/2002

- Uitvoering:

- Hardcover

- Formaat:

- Genaaid

- Afmetingen:

- 172 mm x 279 mm

- Gewicht:

- 793 g

Alleen bij Standaard Boekhandel

+ 838 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.