- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Omschrijving

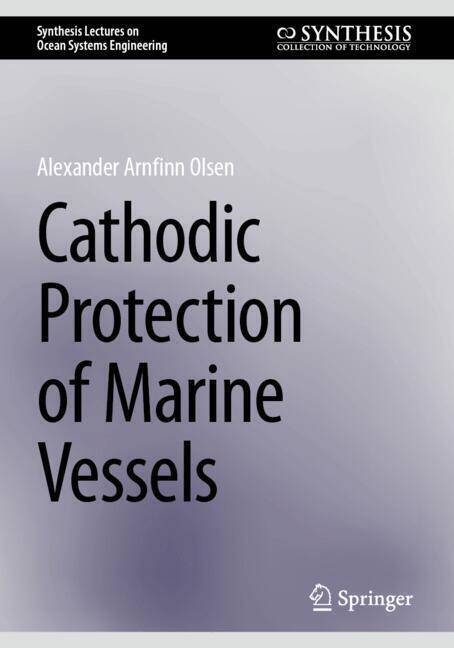

Protective coatings are the most efficient way to protect ship steel structures from corrosion. However, cathodic protection, often in conjunction with protective coatings, is also used to protect immersed parts of bare steel surfaces (including coating damaged areas) from corrosion. This includes the external hull surface and the internal surfaces of tanks, such as ballast tanks. Cathodic protection (CP) can be Impressed Current Cathodic Protection, Galvanic Anode Cathodic Protection, or a combination of both. Cathodic protection controls corrosion by supplying direct current to the immersed surface of the structure, thus making the structure a cathode of a cell. The external hull of a ship is exposed to different waters with differing chemistries, which have a profound influence on the cathodic protection. This short text on Cathodic Protection of Marine Vessels was developed to provide guidelines for ship cathodic protection design, installation, and maintenance given it is a common practice for a ship to have cathodic protection systems installed during its new construction.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 75

- Taal:

- Engels

- Reeks:

Eigenschappen

- Productcode (EAN):

- 9783031775772

- Verschijningsdatum:

- 2/02/2025

- Uitvoering:

- Paperback

- Formaat:

- Trade paperback (VS)

- Afmetingen:

- 170 mm x 244 mm

- Gewicht:

- 158 g

Alleen bij Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.