Wil je zeker zijn dat je cadeautjes op tijd onder de kerstboom liggen? Onze winkels ontvangen jou met open armen. Nu met extra openingsuren op zondag!

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Wil je zeker zijn dat je cadeautjes op tijd onder de kerstboom liggen? Onze winkels ontvangen jou met open armen. Nu met extra openingsuren op zondag!

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

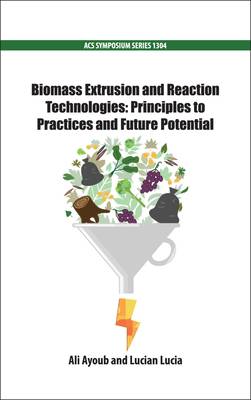

Biomass Extrusion and Reaction Technologies

Principles to Practices and Future Potential

€ 164,45

+ 328 punten

Omschrijving

Reactive extrusion is an environmentally friendly, cost-effective technology that has the potential to enhance the commercial viability of biomass-derived materials. The process can be applied in order to carry out melt blending simultaneously with various chemical reactions including polymerization, grafting, branching, and functionalization. Therefore, production and processing can be integrated in a single stage, thereby reducing or eliminating the need for extensive, high-maintenance equipment. In general, extrusion is being increasingly applied worldwide to manufacture an expanding list of products. During extrusion, product attributes are controlled by feed composition, the length of time the product remains in the extruder, and also the manipulation of specific mechanical or thermal energy inputs as adjusted by many variables such as temperature, moisture, screw configuration, speed, and feed rate. The choice of the extruder type, screw profile, configuration, and

operating conditions can be altered to modify the properties desired in the final product. During the last two decades, the physico-chemical modification of biomass via extrusion has become an important field of research with great potential to produce materials with new properties. New technologies that allow for the efficient conversion of previously unstable materials and/or blending of immiscible polymers offer opportunities for developing new bio-based products with unique properties. Some of these technologies should allow for a nice balance between the desired properties and effective methods for processing to be successful. In addition to the academic interest in these kinds of systems, there is industrial interest due to increasing environmental and economic concerns in recent years. Moreover, replacing existing synthetic procedures with eco-friendly and sustainable processing strategies will open the door to better designed reactors as well as the use of alternative energy resources. One interesting new strategy is to combine supercritical carbon dioxide or irradiation technologies with reactive extrusion to create a wide range of applications in the food and non-food markets. Some examples of applications for biomass-based composites are for filtration devices, membranes, non-woven and paper type products, foams, structural composites, nanocomposites, coatings, fibers, films, biofuels, and electrical devices. The editors believe that in the future many more extrusion reactions will be developed, and that such reactions will help to simplify existing time- and resource-consuming conventional procedures. Extrusion processes offer the potential to transform the use of biomass to produce renewable, sustainable products in ways currently unreported by conventional processes. The future for the application of the extrusion combined technology looks bright on an industrial scale.

operating conditions can be altered to modify the properties desired in the final product. During the last two decades, the physico-chemical modification of biomass via extrusion has become an important field of research with great potential to produce materials with new properties. New technologies that allow for the efficient conversion of previously unstable materials and/or blending of immiscible polymers offer opportunities for developing new bio-based products with unique properties. Some of these technologies should allow for a nice balance between the desired properties and effective methods for processing to be successful. In addition to the academic interest in these kinds of systems, there is industrial interest due to increasing environmental and economic concerns in recent years. Moreover, replacing existing synthetic procedures with eco-friendly and sustainable processing strategies will open the door to better designed reactors as well as the use of alternative energy resources. One interesting new strategy is to combine supercritical carbon dioxide or irradiation technologies with reactive extrusion to create a wide range of applications in the food and non-food markets. Some examples of applications for biomass-based composites are for filtration devices, membranes, non-woven and paper type products, foams, structural composites, nanocomposites, coatings, fibers, films, biofuels, and electrical devices. The editors believe that in the future many more extrusion reactions will be developed, and that such reactions will help to simplify existing time- and resource-consuming conventional procedures. Extrusion processes offer the potential to transform the use of biomass to produce renewable, sustainable products in ways currently unreported by conventional processes. The future for the application of the extrusion combined technology looks bright on an industrial scale.

Specificaties

Betrokkenen

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 288

- Taal:

- Engels

- Reeks:

Eigenschappen

- Productcode (EAN):

- 9780841233713

- Verschijningsdatum:

- 19/09/2019

- Uitvoering:

- Hardcover

- Formaat:

- Genaaid

- Afmetingen:

- 162 mm x 235 mm

- Gewicht:

- 607 g

Alleen bij Standaard Boekhandel

+ 328 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.