- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

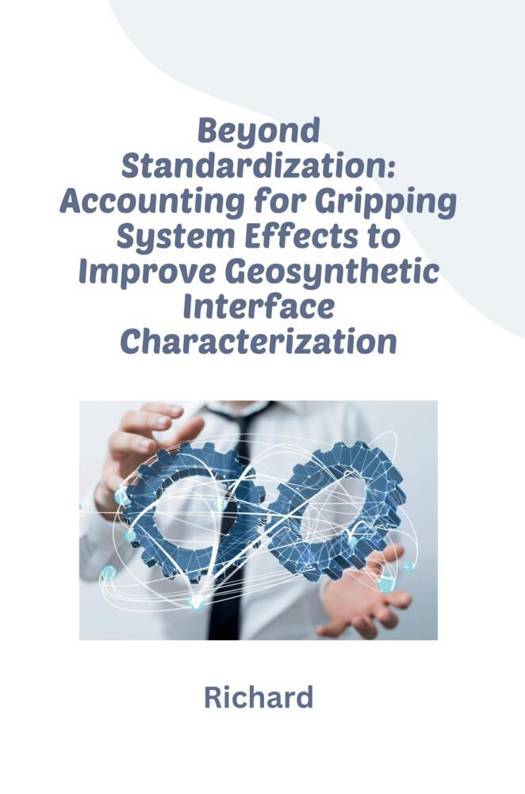

Beyond Standardization

Accounting for Gripping System Effects to Improve Geosynthetic Interface Characterization

Richard

Paperback | Engels

€ 26,45

+ 52 punten

Omschrijving

One of the critical factors in preventing failures of structures that consist geosynthetics is the use of appropriately characterized geosynthetic interface shear friction in the theoretical design of the structure. The interface shear friction parameters such as the frictional angle and adhesion must, therefore, first be determined. The interface friction angle and adhesion are measured in the laboratory mainly using the direct shear apparatus in accordance with ASTM-D5321 and ASTM-D6243 standards (Sikwanda et al. 2018). Although these laboratory tests are standardized, the quality of the results can be largely affected by several factors such as specimen gripping systems, shearing rate, applied normal stress, and the type of geosynthetic test specimens (Fox & Stark 2004). Among these factors, the former is considered to be a major source of dissimilarities in the results (Fox & Kim 2008). This is because when the geosynthetic being tested is not sufficiently secured to the shearing blocks by the gripping system, it experiences progressive failure and shear strength that deviates from the actual field performance (Fox et al. 2004). This could lead to unsafe, cost ineffective, etc. design of projects with the respective geosynthetic materials. This research, therefore, was undertaken to investigate the effects of the specimen gripping system on shear strength at the geosynthetic/geosynthetic interface using a direct shear device.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 124

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9783384241108

- Verschijningsdatum:

- 28/05/2024

- Uitvoering:

- Paperback

- Formaat:

- Trade paperback (VS)

- Afmetingen:

- 152 mm x 229 mm

- Gewicht:

- 190 g

Alleen bij Standaard Boekhandel

+ 52 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.