- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Omschrijving

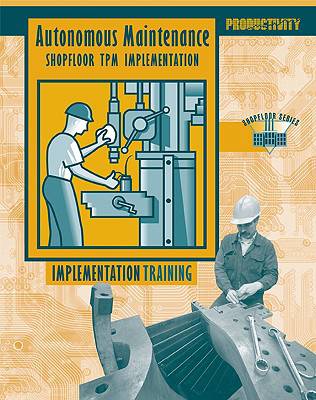

With Productivity's Autonomous Maintenance video training series, you'll learn how to unleash the hidden potential on your shopfloor and dramatically lower your production costs.

Each video takes you inside American companies that have successfully introduced autonomous maintenance. You hear managers, shopfloor maintenance workers and team leaders describing how it worked for them. Employees from both discrete manufacturing and the process industry share their methods and successes in implementing autonomous maintenance. Involving all your employees in maintenance activities will benefit your company, because the people who operate the machines on a daily basis understand the finer details of a machine's functionality. They can spot early signs of problems and save your company money by preventing costly repairs and long delays in the production process.

Autonomous maintenance is part of total productive maintenance (TPM), a team-based approach to maintenance activities. The goal of autonomous maintenance is to prepare operators to do some equipment care independently of the maintenance staff. The program is a partnership between operators, technicians, engineers, and managers in the running and maintaining of equipment. In other words, it is a "we-centered" approach to equipment management. The equipment is "ours" and everyone has a sense of ownership in the maintenance process.

Autonomous Maintenance: Shopfloor TPM Implementation is a team-based program that lays the foundation for other maintenance activities by establishing the basic conditions for a machine's operation.The video set covers the seven-step process for implementing autonomous maintenance:

- Initial Inspection and cleaning

- Eliminating sources of contamination

- Lubrication and establishing provisional standards

- Training for general inspection

- Conducting general inspection

- Improving workplace management and control

- Moving forward with advanced improvement activities

Run Time: 120 Min

FREE Video Demo

Autonomous Maintenance - Shopfloor TPM Implementation Video Series To view

click on your connection speed! This video requires Windows Media Player and a sound card (28.8K, 56K dial-up) 4.35 minutes, 1.28 mb (ISDN, DSL, Cable, T1) 4.35 minutes, 8.89 mb Click to install

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 134

- Taal:

- Engels

- Reeks:

Eigenschappen

- Productcode (EAN):

- 9781563273377

- Verschijningsdatum:

- 1/03/2006

- Uitvoering:

- Boek

- Afmetingen:

- 282 mm x 302 mm

- Gewicht:

- 2177 g

Alleen bij Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.